You may have heard of LED light sheet, but do you truly understand what it is? This article will give you some practical information, helping you gain a deeper understanding of LED sheet lighting.

What are LED sheets?

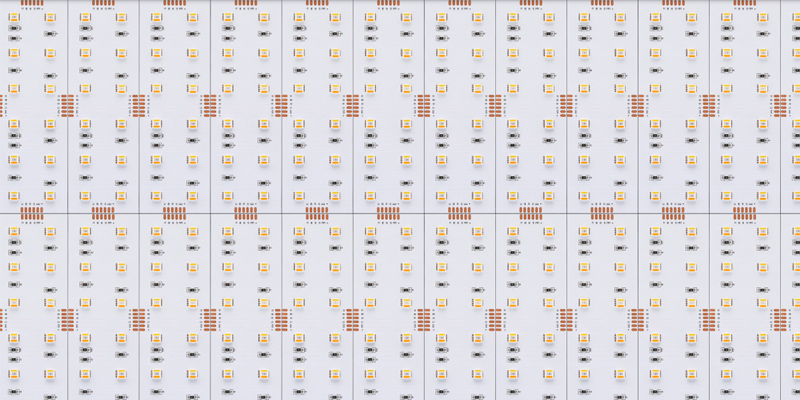

An LED light sheet is a flexible sheet embedded with numerous LED chips that work together to emit uniform light. Sheet lights LED can be cut into different shapes. You can also easily bend and fold it to fit curved surfaces. Flat LED sheets can be spliced together to cover wide areas, so these LED sheet lights are an ideal solution for extensive and irregularly shaped lighting applications.

Nowadays, LED sheet lighting are widely used in bars, restaurants and retail stores to backlight stone, including marble and onyx, as well as other translucent materials like glass and acrylic. Besides, they are also favored by designers for signage lighting projects.

There are single color, dual color, RGB, RGBW, RGBWW and programmable LED sheets for you to select.

| Type | Single White Color | Tunable White | RGBW | RGBCCT | RGBIC |

| LED Chip: | SMD2835 | SMD2835 | SMD5050 | SMD5050 | SMD5050 |

| Input Voltage: | 24V DC | 24V DC | 24V DC | 24V DC | 12V DC |

| Working Power: | Max 28W | Max 40W | Max 48W | Max 60W | Max 13W |

| Light Color: | 1800K-9000K selectable | 2700~6500K | RGB+3000/4000/6000K | RGB+2700K-6500K | RGB+IC |

| LED Quantity: | 242 LEDs | 242 +242 LEDs | 288 LEDs | 360 LEDs | 100 LEDs |

| Cut Unit: | 0.87″x0.87″ | 0.87″x0.87″ | 0.8″x4.8″ | 4.92″x1″ | 0.98″x0.98″ |

| CRI: | 90+ | 90+ | 90+ | 90+ | – |

| Product Size: | L19.2 “x W9.6” | L19.3 “x W9.6” | L19.2 “x W9.6” | L19.7 “x W9.6” | L9.8″x9.8″ |

With the help of a controller, these LED light sheets provide different colors according to your needs. People usually choose RGB LED sheet and place it underneath marble to emit a quiet, artistic glow through marble’s natural veins, creating a luxurious and elegant ambiance. Click below PDF to learn more.

Mainly used for:

- Stone backlighting

- Marble Backlight Decoration

- Backlighting Stained Glass

- LED Channel Letter Lighting

- LED Modules for Signs

Is LED light panel sheet as thin as paper?

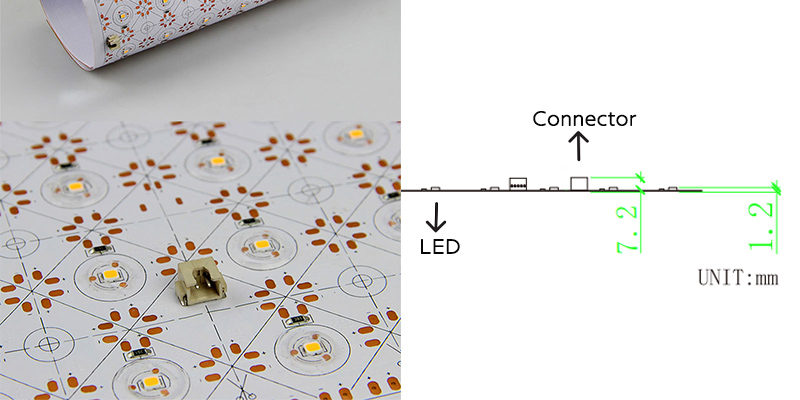

People often say paper thin led light sheets, but are these LED sheets really as thin as paper? In fact, LED light sheets are slightly thicker than ordinary A4 paper and feel more like cardboard used for making posters.

Ordinary A4 paper is 0.1mm thick, while an LED light sheet panel is 0.5mm thick. However, including the height of LEDs, the overall thickness of the sheet LED is 1.2mm. If the LED sheet is mounted with connectors, it will be much thicker, around 7mm.

Can you cut these LED light sheets?

The answer is yes. The major strength of LED lighting sheets is that they are cuttable. There are black horizontal, vertical and even 45° diagonal lines marked on the sheets to guide your cuts.

Using scissors, you can cut the shapes you want along the black lines and fit cuttable LED sheet into recesses or grooves where space is limited. The smallest cutting unit is an LED. But remember to apply RTV silicone sealant or conformal coating to the cutting edge if it has contact with conductive surface.

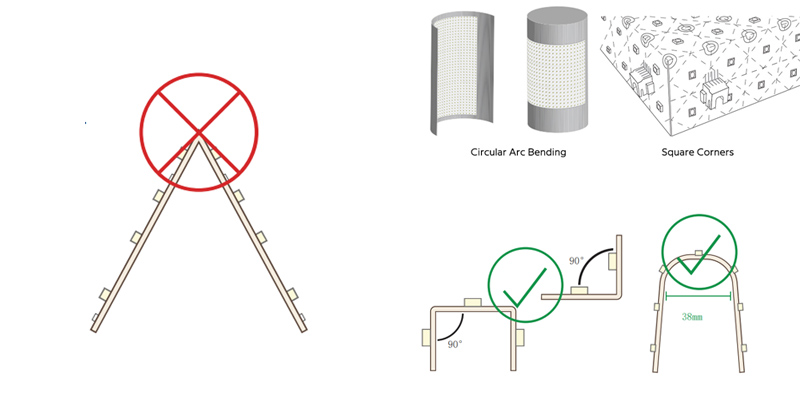

Can you bend or fold Sheet LED?

In essence, LED panel sheet is flexible sheet, so of course you can bend them. Whether it is a circular shape or wavy shape, flexible LED sheet can perfectly meet your needs. But there are specific guidelines you need to follow when bending. You can’t bend it at sharp angle because it will damage the circuit board, but 90-degree hard bends and soft bends are acceptable.

At the same time, you can also use flexible LED light sheet to form square corners, but make sure that the corner edges fit the black cutting line on the sheet and not just randomly fold it over. For further bending information (e.g., how to cut and make square corners), please check PDF attached.

How to connect different pieces of sheet LED?

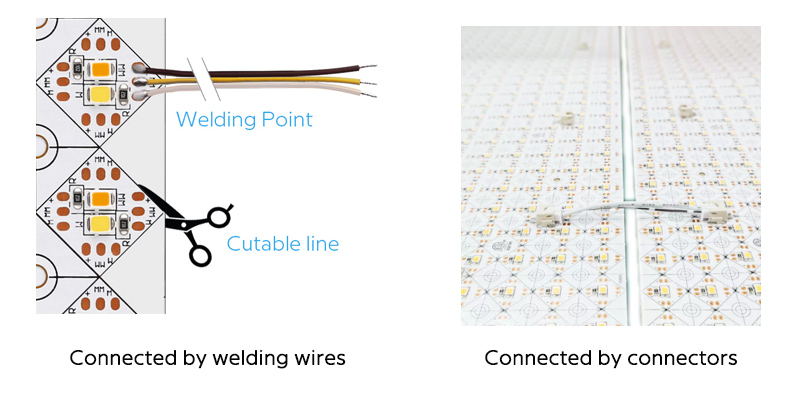

Sheet lights LED can be connected in two primary ways, by wires or by connectors.

If you want to solder by wire, each LED has pinpoints on the top, bottom, left and right side for you choose. The power consumption of a single LED sheet is about 300W, and we recommend using 20AWG wire to solder. If connecting multiple sheet lights LED, it is recommended to use 18AWG wire. 16AWG wire is too thick to fit well into the pinpoints, so please avoid it. We provide high-quality LED light sheets at the best price as well as corresponding soldering wires, and we also offer soldering service.

Connectors mounted on the sheets are also a good way to connect, lightweight and fast, plug and play. What’s more, the connectors can be removed at will. You just need to hold the LED sheet panel and turn the connectors clockwise or counterclockwise with pliers, then they will be easily loosened.

What are LED sheet lights used for?

LED sheets for backlighting

In clubs, bars, high class restaurants or hotels, you must have seen uniformly illuminated marble or onyx, which are either mounted on table tops or wall surfaces. The unique veins of the stone leave shadows in the light, creating a unique atmosphere in dark environments, impressive and refreshing. This remarkable lighting effect is all thanks to the LED backlight sheet.

In addition to marble onyx stone, LED panel sheet can also be used to backlight other translucent materials such as stained glass.

LED sheets for signage lighting

Lots of people use LED sheets to do signage lighting. They cut these sheets into different letters or shapes they want, place them in the corresponding large letter forms, and cover them with diffusers.

Compared to modular lights on small hard boards, LED sheet light have higher density of LEDs, so they are able to give off a more uniform light. However, LED sheeting is not waterproof and can only be used indoors.

LED sheets for large scale commercial ceiling lighting

Modular LED sheets can be connected with each other easily and are designed to serve long time, so they are also an ideal solution for large-scale commercial ceiling lighting project. Light pieces are fastened to the ceiling and covered by translucent flat panels, therefore provide continuous and seamless illumination. Clean, bright and attractive, these sheets are widely used in hotel lobbies, garages, warehouses and shopping malls.

Apart from backlighting, letter lighting, and large scale commercial ceiling lighting, LED sheets have many applications, such as billboard lighting, retail displays, museum displays, trade shows, and even home lighting. They are cleverly designed to realize both large area illumination and edge accent lighting.

How to install LED light sheet?

LED lighting sheets come with adhesive backing. Just simply remove the backing paper and adhere these LED sheets to wherever you want. All can be done within a few minutes, much more convenient than nails and screws.

Step-By-Step Guide

1. Measure the size of the board you want to paste LED backlight sheet on, and determine the size and quantity of LED sheets you need to purchase accordingly.

2. Connect LED sheet lights together by wire or connector.

3. Choose right power supply and controller for LED panel sheet.

Principle: The voltage of the power supply should be the same as the voltage of LED sheet. And the driver wattage should be 1.2 times the the total wattage of LED sheets.

For example, when you need to power 4 pieces of 24V 60W LED lighting sheets, the voltage of power supply should the same, also 24V. And the total wattage of 4 pieces 60W LED sheets is 4pcs x 60W=240W. So the wattage of power supply will be 240W x 1.2=288W. (Or a little bit above)

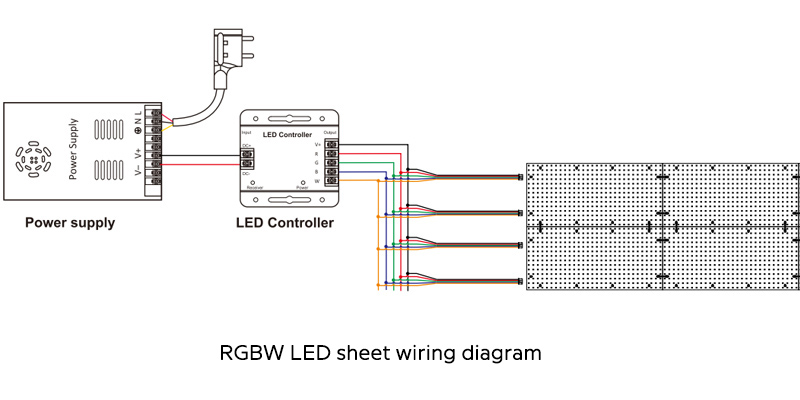

4. Connect power supply and controller to LED light sheet panel, turn them on and ready for use.

How to connect? Click for further information about LED sheeting installation.