There are many ways to use LED strip lights without a plug. This article will lead you to know 10 easy ways about how to use LED strip lights without a plug, from using battery strip lights to applying jumper wires and breadboards. After reading, you will also learn about common mistakes when powering strips and tips for connecting LED strips without plugs. It is believed that you will find the most appropriate solution for your projects or problems.

Do LED strip lights need to be plugged in?

LED lights that don’t need to be plugged into a wall outlet need some form of power source to function. These alternative LED strip power sources offer flexibility in how strip lights can be used, catering to various needs and environments.

10 Easy Ways To Use LED Strip Lights Without Plugs

Ensure that whatever alternative power source you choose provides the correct voltage and current for your light strips to operate safely and efficiently. Always follow the manufacturer’s guidelines and safety precautions when working with electrical devices.

Power LED Lights With Batteries

Standard disposable batteries like AA or AAA, lithium rechargeable batteries, or battery packs made especially for LED lights can all be used for these special battery-operated LED strip lights, which are normally used for indoor applications, like under a cabinet or under a counter, because of the light strip battery’s operating environment. So it is important to choose suitable battery-operated LED tape lights with the appropriate voltage and capacity.

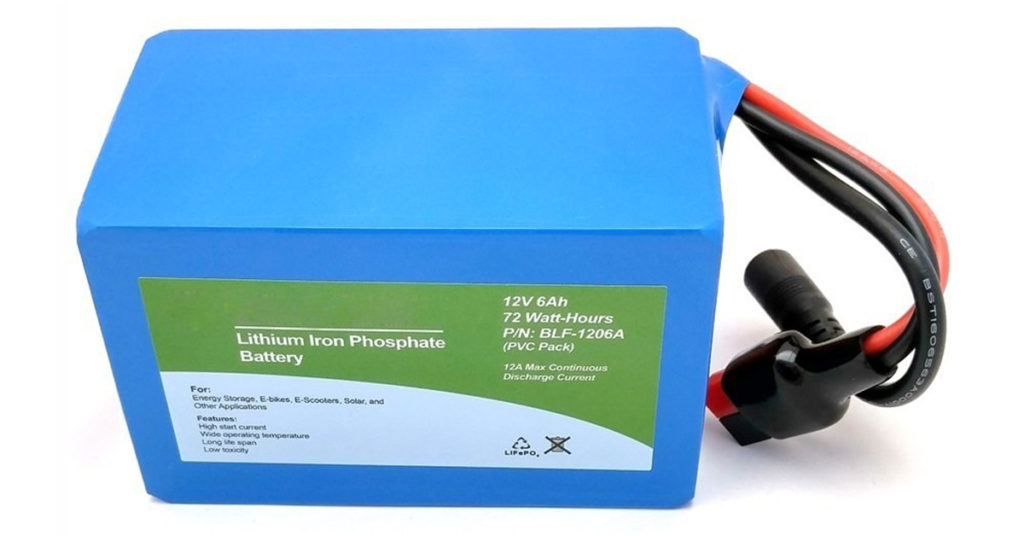

Take a 12V LED Light Strips Lithium Iron Phosphate Battery for example. Watch this video to check out how to use it.

Its relevant parameters are below:

| Input power | 110V or 220V AC to DC |

| Output Voltage | DC12V |

| Power | 72W |

| Current | 6A |

| Plug Type | US/EU |

| Work Temperature | -20℃-60℃ |

| Rechargeable | Yes |

| Case Type | PVC pack |

| Dimensions | ( L*W*H ) 4.4in*2.6in*2.8in ( 108mm*64mm*69mm ) |

| Charg Connector | DC Barrel Plug |

| Certification | CE, FCC, RoHS |

| Rechargeable times | 1000~1200 times |

| Waterproof | Non-waterproof IP20 |

| Applicable | 3528/5050 LED lights, LED module string, LED lighting products |

If you want to know more about LED light strip batteries, please visit this website, where you will find the appropriate strip lights with battery packs.

Use LED strips with USB

USB ports and another connector can be utilized for USB-powered LED light strips, which makes them easy to be charged by gadgets like televisions, cars, USB wall adapters, power banks, and computers. There is one point that needs to be focused on, which is that they are run on 5V. If they are driven by 3V, they can still work but are not so bright. If they are driven by 12V, they might be destroyed.

Powered With A Power Bank

The majority of the time, low-voltage DC power powers LED lights. You can power the lights in different settings with a battery bank. LED strips that are powered by a power bank are portable and can be used anywhere there aren’t any electrical outlets. Because of this, these movable LED strip lights are perfect for camping, outdoor gatherings, and other scenarios where mobility is crucial. We describe the precise procedure in our video.

Powered With a DC Power Adapter

To power your tape lights, use a DC power adapter that is rated for the right voltage and current. While the current rating should be adequate to power the whole length of the strip, the voltage rating should correspond to the specifications of the strip lights.

Power LED Light Strips With Solar

Certain strip lights are matched with solar panels to use, which aim at taking advantage of the sunshine to generate electricity to run the lights. Apparently, they are frequently used in outdoor applications with access to direct sunlight. Two points need to be taken into account. One is to choose LED lights with high quality and a great IP rating, and another is that the voltage of solar panels and tapes should be the same.

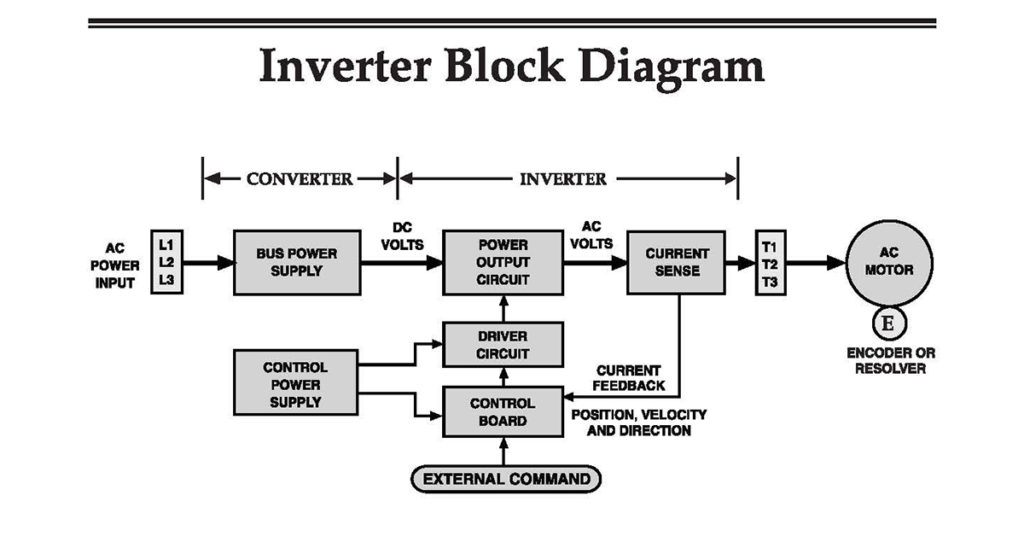

Run With Inverters

Another popular way to power LED tape lights is via an inverter, particularly if you’re working with several kinds of LED light strip adaptors or need to convert DC power to AC power. Undoubtedly, using an inverter to convert DC power from a battery or solar panel to AC is wasteful and might result in energy loss. This inefficiency is eliminated directly by using a DC power supply for LED strip lights. Regarding how inverters work, this article from IRTF will answer most of your questions.

Hardwire To A Fused Connection

Compared to plug-in adapters, hardwiring LED strip lights to a fused connection is a more permanent and expert installation technique.

Typically, LED lights need a low-voltage DC power source if they are not special ones like 110V, 120V or 220V high-voltage LED light strips. You don’t need an additional transformer if the driver already delivers the low voltage (12V or 24V DC) needed by the LED tape. A transformer is necessary to convert the power supply voltage to the necessary low voltage if it is higher (such as 120V or 220V AC).

If you’re not sure you can handle electrical work, think about getting a professional electrician to do the installation.

Use An Extension Cord

It’s crucial to remember that when there isn’t a nearby power outlet, powering LED lights with an extension cord is a practical solution. This is to extend the length to connect the location of the power source.

This is also used when combining two or more light strips for greater brightness or other purposes. There is also a case for a better arrangement to keep the lighting effect. For instance, when the brightness of the strip is uneven, use an extension cord to connect the LED strip to the power supply. Note that the location is at the maximum length of the strip within the normal operating range, which means no voltage drop. Generally, 5 meters is the long run length of LED lights.

Getting an extension cord with the right length is essential if you are in situation 1. Otherwise, safety should always come first. To prevent overloading or other electrical dangers, make sure the extension cord’s wire gauge is sufficient to withstand the current and power of the integrated strips and that all connections are made securely.

Wire A Ribbon Cable

You can also directly wire an LED tape light to a ribbon cable for power without using a plug. However, you’ll need to ensure that the voltage and current requirements of the LED tapes match what the ribbon cable can handle. Additionally, you’ll need to properly solder or interconnect the wires from the strips to the ribbon cable to ensure a secure joint.

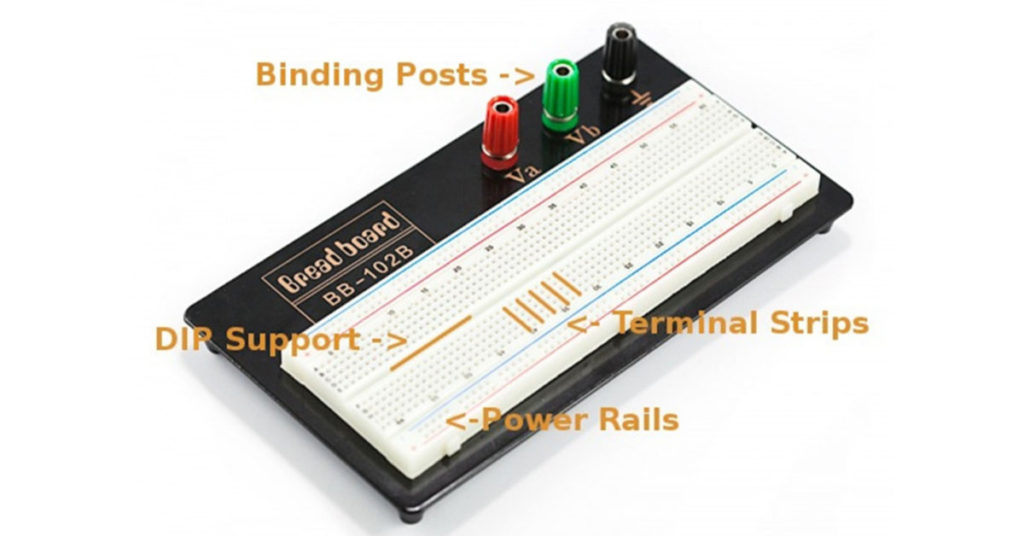

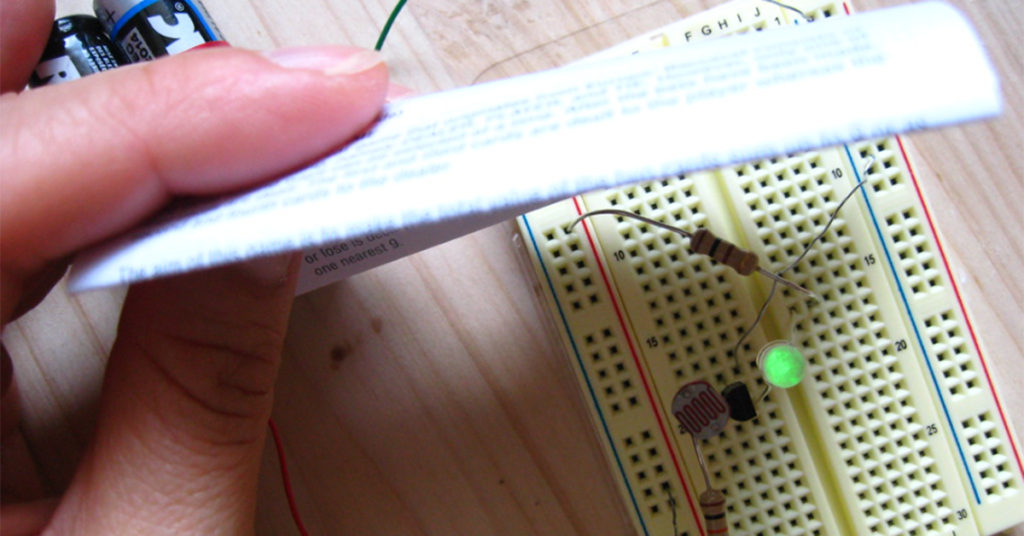

Powered With Jumper Wires And Breadboards

Combining jumper wires and breadboards is a way of using LED strip lights without power plugs. Suppose that the positive (+) and negative (-) terminals of the driver are already connected to the power rails of the breadboard separately, and all insertion happens on one side of DIP support (the ravine in the middle of the breadboard), which is easy to understand and operate. It is recommended to know the terminology to understand it clearly; just visit this website to get more details.

Insert the (+) and (-) of the light strip’s wire into two different terminal strips (rows). Two jumper wires are each inserted into other holes on the same row as (+) and (-) of the tape light, and then the remaining terminals of the jumper wires are inserted into the power rails (positive and negative poles) of the breadboard respectively.

Common Mistakes When Powering LED Strips Light Without Plugs

When powering LED strip lights with no plug, there are some common mistakes that we need to avoid. So before installing strips, please pay attention to the following points: If not, there might be some inevitable and unexpected accidents happening, which might cause fires and destroy your strips.

Reverse Polarity

Reverse polarity is almost the most common mistake in powering tape lights. Connecting the positive and negative wires of the LED lights incorrectly can cause the lights to not function or potentially damage them. Double-check polarity before operating.

Poor Connection

Poor connection is one of the most prevalent, yet often forgotten, faults made while using LED strips. Partially soldered joints or loose wire integration into the LED tapes might cause malfunctions or sporadic performance. To avoid short circuits, make sure all joints are tight and adequately insulated. In addition, inadequate solder connection insulation might result in exposed wires or short circuits, both of which are dangerous. Heat shrink tubing or electrical tape can be used to shield and insulate links. Watch this video to check how to connect LED strip lights together without connectors.

Incorrect Voltage

Another frequent error made when powering LED tape lights without plugs is using the wrong voltage. The incorrect voltage from the driver may cause unpredictable voltage output, which could harm the strips or cause uneven brightness. The LED lights will break if the driver voltage is significantly higher than the voltage of the lights. In the event that the power supply voltage is significantly lower than that of the LED lights, the latter may not function as intended. Make sure to match the voltage rating of LED lights with the adapter at all times.

Overloading the Wire

Overloading the wires fusing LED strips without connectors is another frequent mistake. Overloading the wire with too much electricity might result in overheating and perhaps ignite a fire. Verify that the wire can carry enough current to meet the power needs of the strip lights.

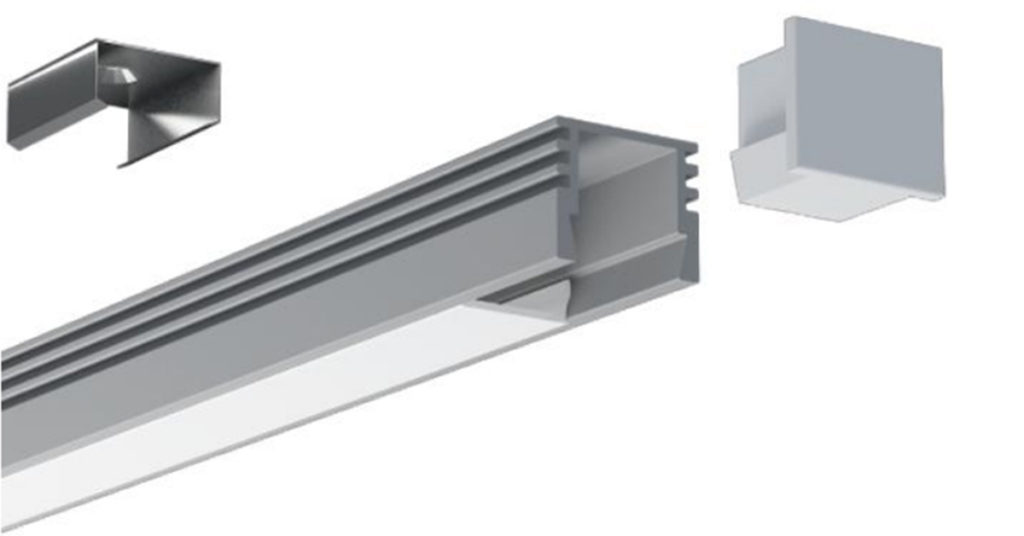

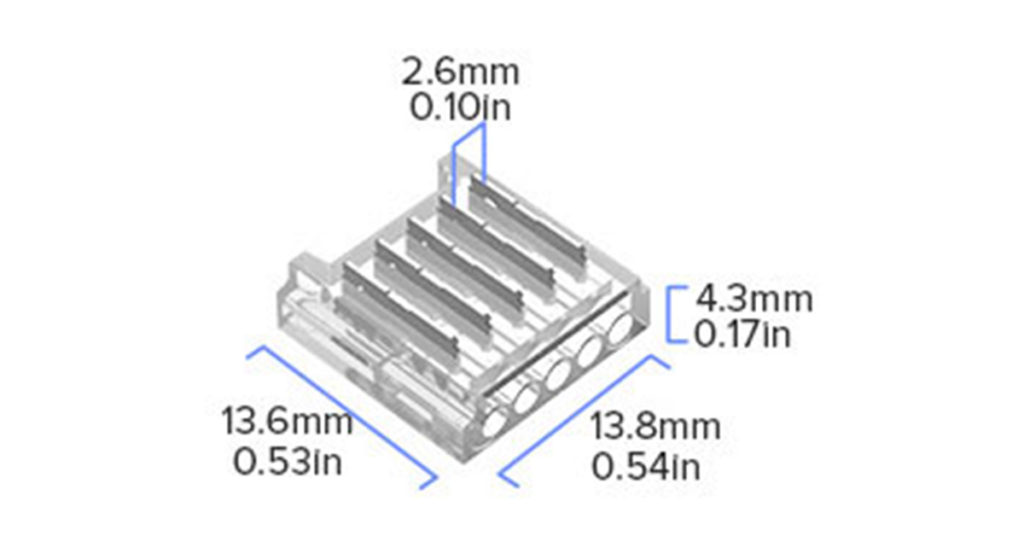

Inadequate Heat Dissipation

LED lights can generate heat, especially when operated in silicone tubes or at high efficiency or brightness. Overheating and premature failure will happen without proper heat dissipation. Use aluminum profiles where necessary. They have not only an exquisite appearance, but their heat dissipation is also remarkable. This PDF will give you more information.

Inaccurate Measurement of Installation Area

Inaccurate measurement of the installation area is an easily ignored mistake when installing no plug-in LED strip lights. Normally, the length of LED strips or wires is easy to get wrong when you prepare to measure the length. Apart from that, whether there is an outlet nearby or not is truly essential. If this point is neglected, many troubles will be caused, like soldering a long wire to be powered by another distant outlet. But perhaps the wire is visible and hard to hide, which doesn’t look so pretty. So be careful to measure the installation area when installing LED strips.

Tips For Connecting LED Strip Lights Without Plugs

When using LED light strips without plug, connecting will be an important link. Before installing them, knowing some tips will help avoid simple mistakes and unnecessary waste. The following are tips for combining strip lights.

Use Solderless LED strip light Connectors

Transparent and solderless connectors are convenient for LED lights, and will not press or damage the LEDs. Take this 5-pin LED strip connector for example.

This type of transparent connector for lights will also not affect the seamless lighting effect. It is firm to gather LED tapes and not easy to pull off.

Choose A DC Power Supply

Compared with other power sources, like solar panels, a DC driver is an efficient way to power LED lights. It has less energy loss, and it’s more environmentally friendly than sticking LED strip lights on solar panels. Meanwell power supplies are well-recognized in the industry due to their high quality.

Distribute Power Evenly

In order to avoid voltage drop and guarantee consistent brightness, longer LED strip installations might want to think about dispersing power throughout the strips’ length. If more than one power source is required, power injection points can be used.

Use Waterproof Heat Shrink Tubing

Make sure the joints are tight and secure when utilizing connectors or soldering to avoid them falling loose over time. For connection insulation and protection, use electrical tape or heat shrink tubing.

If the strips are installed in damp or outdoor environments, heat shrink tubing can be waterproof to some extent. It is recommended to use waterproof connectors or apply silicone sealant to the links to protect them from moisture and corrosion.

Test Before Installation

Everything is operating as it should. Test the connections and functionality before permanently installing the LED lights. This makes troubleshooting any problems easier.

Final Words

In conclusion, utilizing LED strip lights without traditional plugs offers a myriad of creative possibilities for illuminating your space, whether opting for battery packs, USB connections, solar panels, or other alternative power sources. However, it’s imperative to prioritize safety precautions, select high-quality components, and adhere to proper installation techniques to ensure the longevity and efficiency of your lighting setup. Whether you’re embarking on how to DIY LED tape light project or enhancing your existing space, these alternative power options might make your unique needs come true.