Wiring a led light is not a hard thing. When you see these names, tunable white light led strip lights, dual white light led strips, and white light adjustable led strip lights, don’t doubt that they are all CCT LED rope lights.

The tunable white led strip has two white lights with different color temperatures, generally a warm white color temperature and a cool white color temperature. When the two color temperatures are neutralized, that is, when the two color temperatures are turned on at the same time, a new color temperature which is the natural white light will be obtained.

| • Tunable white CCT led strip: DC5V, DC12V, DC24V, Single-row, Double-row, Quad-row • Constant current CCT long led strip lights: DC24V, DC48V • COB CCT led strip lights: DC12/24V • Addressable CCT led strip: DC5V, DC12V, DC24V |

Notice the Voltage Drop During Installation

During the circuit transportation of the low-voltage led strip lights, due to too many parts of the led light strip, there will be energy loss, which is manifested as a voltage drop, resulting in the inconsistency of the brightness and color of the led strip.

This is an issue that deserves important attention. The current solution to the voltage drop is to provide enough power to the led tape to make up for the consumed power. The longer the led strip length, the more obvious the voltage drop.

| 5V CCT white led strip lights ⇒ power supply at both ends at 5 meters 12V CCT led strip lights ⇒ power supply at both ends at 10 meters 24V dual white led strip lights ⇒ power supply at both ends at 15 meters |

How to Power the Tunable CCT LED Strip?

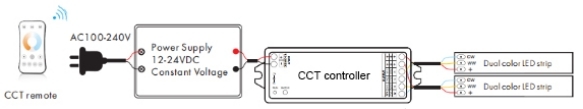

To control the tunable CCT led strip, an CCT LED controller must be installed. The led light controller is installed between the led strip and the led power supply.

The led power supply has an important criterion, the rule 80%, the power consumption of the dual white led strip light should not exceed 80% of the power supply, and the led controller is too. So the power of the power supply and the led controller are the same.

If your led strip requires 96W, you need to prepare a 115.2W led power and a 115.2W led controller.

Circuit overload is a bad thing, it will get hot and even burn out the equipment used, which poses a great safety hazard. Therefore, when using the led power supply and the led light controller, please give them some space to maintain the service life.

►1. First, understand the tunable white led strip structure.

CCT led strip lights have three connection points, one is the cold white signal line, one is the warm white signal line, and a positive line. The lines that represent the color are negative lines.

►2. Second, connect the CCT white led strip to the same logo on the CCT led controller.

►3. Third, connect the led light controller to the led power supply.

Note that the positive and negative poles should not be reversed. The red wire is the positive pole and the black wire is the negative pole.

Sometimes we don’t just connect one led strip, there will be situations where we need to connect multiple led strip lights. The more the number of tunable white led strip lights connected, the greater the power required.

| CCT led strip number | Power | LED power supply power | LED controller power |

| 1 | 96W | 115.2W | 115.2W |

| 2 | 192W | 230.4W | 230.4W |

| 3 | 288W | 345.6W | 345.6W |

How to Wire Your Large LED Strip Project?

The project length is very long, how to connect the tunable white led strip?

The simple method is to choose constant current long led light strips with no voltage drop, the wiring is simple, and the cost is low. But if you have already bought the led light strip and don’t know how to install it, you can use the following wiring methods.

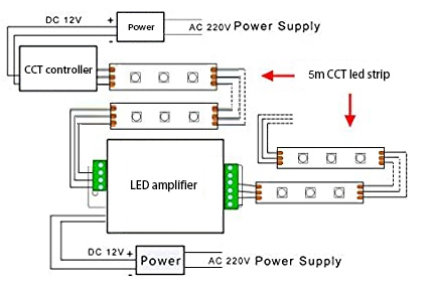

1. Use the LED signal amplifier

The function of the led amplifier is to amplify the attenuated signal to provide sufficient power for the adjustable led strips behind.

When and how to use the amplifier?

1) CCT LED Controller overload ⇒ Separate the CCT led strip lights with an led amplifier to ensure that the power of the controller can withstand the strip it is connected to.

2) CCT led strip ultra long distance ⇒ Use an led amplifier between led strip lights.

3) Parallel multiple CCT white led strips ⇒ Connect the next led strip in parallel with an led amplifier.

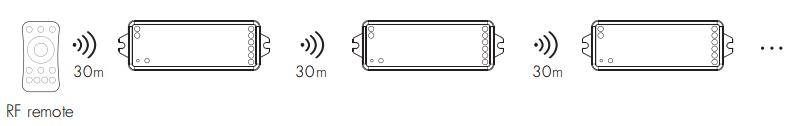

2. Use RF CCT LED controller

1) The single-zone color temperature remote simultaneously controls multiple RF CCT led controllers.

The led light remote control has a barrier-free distance of 30 meters and has a cascade function. The led controller automatically forwards the RF remote control signal, and the led light controller automatically synchronizes the control to achieve a control distance of hundreds of meters.

2) The multi-zone color temperature remote controls multiple RF CCT led controllers.

Each zone of the multi-zone color temperature remote control can be paired with one or more RF led controllers to achieve zone and synchronous control. An RF controller can be paired in different zones of the same remote control to achieve flexible grouping functions.

In addition, you can also use the multi-zone color temperature panel remote control and the mobile APP installed on IOS or Android mobile devices while working with WiFi-Relay controller to control multiple RF CCT led controllers.

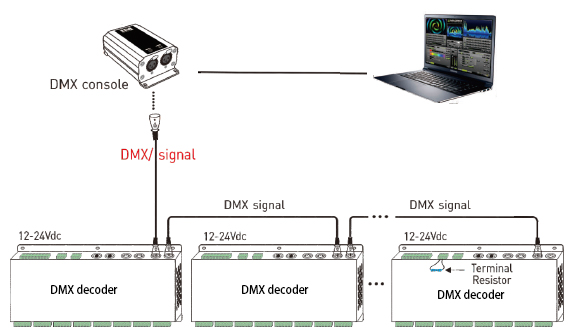

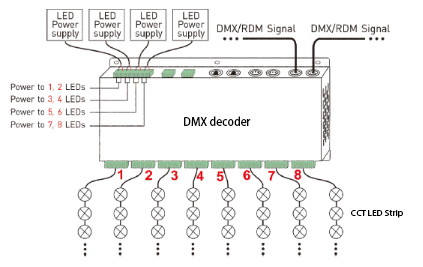

3. Use DMX decoder

The DMX constant voltage decoder converts the standard DMX512 digital signal into a constant voltage PWM signal, and adjusts the output of the DMX decoder through the DMX master control to achieve 0-100% non-flicker dimming.

The DMX address can be set via the digital tube/OLED screen button or 10-digit DIP switch, or it can be set remotely via the DMX512/RDM console. Commonly used for commercial lighting purposes.

Hope that this article can help you.