How to Connect LED Strip Lights?

Correctly connecting LED strip lights is a fundamental part in the use of strip lights. When you tend to decorate your room with DIY LED strip lights, but you do not know how to connect LED strip lights. Here you will learn the LED strip light connection method.

Before installing LED strip lights:

1. First you have to measure the length of your preferred installation place.

2. Second, mark the cut location according to the length. Ensure that you can’t cut a wrong position.

3. Third, cut the LED strip light with a shape scissor along the cutting line. Do not cut to other locations, otherwise, it will cause a section of the LED strip light not to light up.

More knowledge :

Can you cut led strip lights? What happens if you cut an led strip?

What you need to know about led strip installation:

How to connect two light strips together?

How to wire single color led strip lights?

How to wire tunable white/CCT led strip lights?

How to wire RGB color changing led strip lights?

How to wire RGBCCT led strip lights?

How to wire addressable led strips?

How to connect LED strip lights together?

There are two ways to connect LED strip lights together, soldering or using LED strip light connectors. Which one is more suitable for you? You can accord to their advantages and disadvantages to choose.

How to connect led strip lights without connectors?

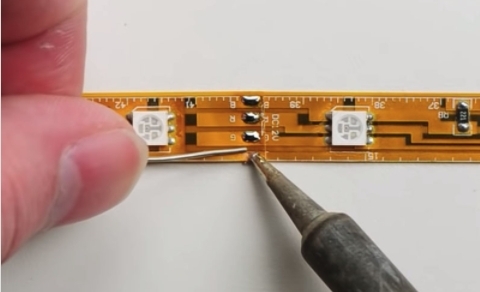

Soldering is a more stable way than using connectors. Performance is almost the same before and after soldering and it almost has no influence to LED strip lights. But it requires you have soldering tools. And the operation is required you to have certain soldering skills.

How to solder wires to led strips?

5 steps to soldering led strip lights:

|

►Step 1. Keep the tip of the soldering iron clean. Rub a few times on the sponge that is full of water. It is not only to temporarily cool down the temperature, but also to rub off the excess tin on the tip of the soldering iron. Be careful not to burn your hands. ►Step 2. Hold the wire in your left hand and the soldering iron in your right hand. During soldering, remember to wear gloves. Don’t breathe in the smell which is harmful to health. ►Step 3. Lightly touch the tinned part of the wire to the solder joint of the LED. Tap lightly with the soldering iron, and pay attention to the tip of the soldering iron touching the two objects at the same time. ►Step 4. Stay for a few seconds and leave at an angle of 45°. ►Step 5. After sticking firmly, connect the power supply to see if the strip light can light up. |

Precautions for soldering:

1. The solder wire contains a certain amount of heavy metal lead, which is harmful. Wear gloves during operation or wash hands after the operation.

2. Do not touch the tip of the soldering iron with wires and other sundries to avoid burns or leakage.

3. Be careful not to solder on a metal pad, as the temperature of the soldering will not rise due to the better heat dissipation effect.

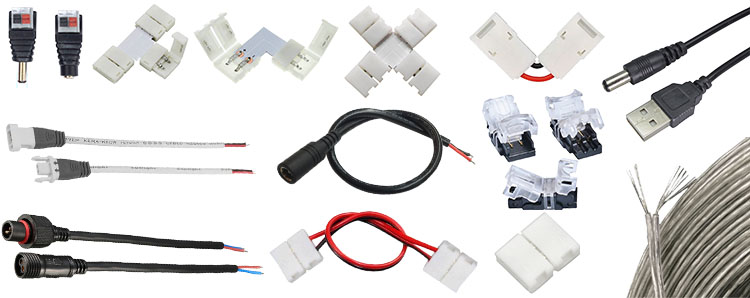

How to connect led strips without soldering?

Using LED strip light connectors is very easy. Slide the open end of LED strip light into the connector and close it to lock it in. Although the operation is convenient, there are still areas to be aware of. If the power of LED strip light is too high, it will burn the connectors. And sometimes it has poor contact.

L shape LED strip light connectors are suitable for corners, where need to change direction. - shape connectors are suitable for straight direction or over obstacles. And there are T shape and + shape connectors, meeting different demands.

In addition to the strip-strip connector, there are also strip-wire connector used to connect strip lights to other wire interfaces, and wire-wire connector which connects wires and wires.

Choose the perfect LED strip light connectors for your project.

Which one is better between soldering and led connectors?

| Soldering | LED connectors |

|

• Require soldering technology and knowledge • Need soldering equipment • The connection is more stable and reliable • Not easy to loosen and fall off • Long duration |

• Simple and convenient operation • Easy to install and remove • Affected by the power of led strip light • May be loose or poor contact |

Considerations to connect multiple LED strip lights

Connect an LED strip light to an LED power supply is easy. But what if there are multiple LED strip lights? First to consider this two questions below.

Is there a voltage drop?

When you connect LED strip lights in series, you will find that the brightness and color get darker as the length of LED strip lights becomes longer with one power supply. Because LED strip lights have voltage drop. To make sure the brightness of LED strip light is the same, you can add another power supply in the end or connect an amplifier. An amplifier is placed between two LED strip lights, and it should be connected to the power supply.

Do I need an LED signal amplifier?

The color of the color changing LED strip lights can be changed after the controller is equipped. But the controller has a certain power, and it cannot bring unlimited LED strip lights. It needs an amplifier to amplify the signal of the controller, and then give the strip lights signal, so that a whole color changing LED strip light can work normally. If you don’t add an amplifier, the color changing strip light in the end will be very dim until it doesn’t light up.

How to connect multiple LED strip lights?

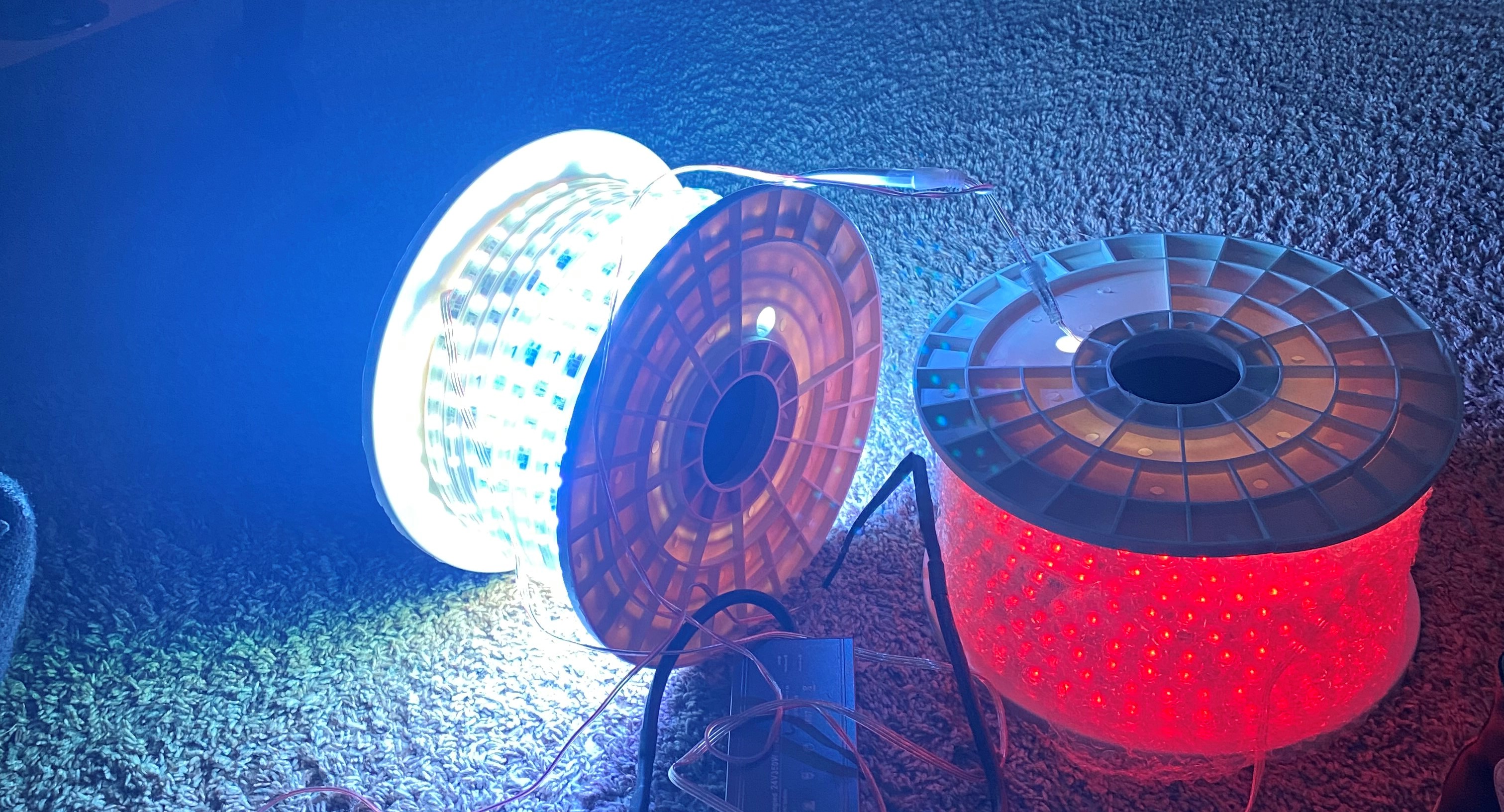

If you want to connect a 20-meter RGB color changing LED strip lights, typically an LED strip light is 5 meters a roll, and it means that you have to connect 4 LED strip lights. If total power of four LED strip lights is 200W, the power of the power supply and the controller need to be 250W.

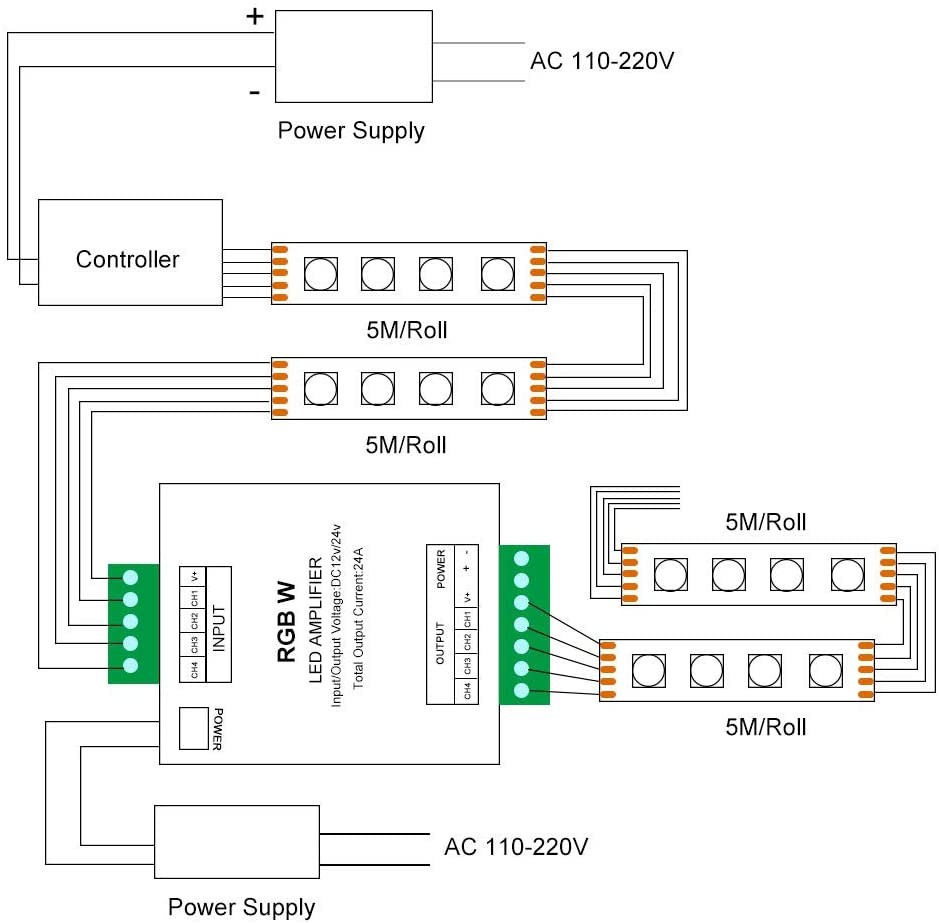

1. Traditional wiring method - Use Signal Amplifier

One connection method is that, power supply connects to controller, and the controller connects to 4 LED strip lights in parallel.

Second connection method, use an amplifier. The function of the amplifier is to amplify the signal that is weakened due to a long distance, so that the brightness and color of all the strip lights look the same. Power supply is connected to controller, and controller is connected to LED strip lights, and the amplifier is connected between every two strip lights.

The amplifiers need to be powered separately. You can also share a power supply with the controller, but pay attention to the power problem. Because in this way, the total power used by the power supply becomes larger, because you need to power the amplifiers, then you need a more powerful power supply to run.

But the use of amplifiers has a disadvantage, that is, it is not suitable for super long projects like 100 meters or 200 meters. If the distance is too long, the signal transmission will be delayed. You may have to wait a few seconds to light up the strip lights at the end.

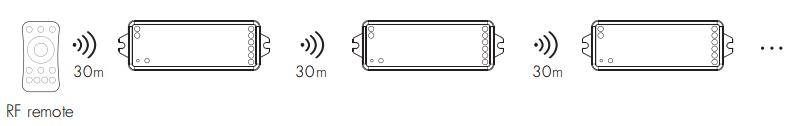

2. Emerging wiring method - RF Wireless Control

Use the radio frequency controller to connect the RGB color changing LED strip lights. Power supply connects controller, and controller connects a strip light. And connect four groups strip lights in this way. Each group can be controlled individually.

The advantages of radio frequency control are that, the wiring is simple and not so complicated, and multiple controllers realize automatic synchronization, which can be controlled by mobile phone APP, RF remote control, touch wall panel, and intelligent voice control.

Note that the maximum distance between each RF controller is only 30 meters. Be careful not to exceed the maximum distance when connecting.

Overall, when you are connecting multiple LED strip lights, you have to ensure that it can normal work. Notice the voltage drop problem and the power can support the work. There is no doubt that the LED strip lights must be charged for normal use. Please pay special attention to this during the use of the LED strip lights.

How many led strip lights can you connect?

While connect multiple LED strip lights, the first thing we should pay attention to is the maximum number of connections of the strip lights. In general, the number is determine by led power supply. The total power cannot exceed the power of the power supply. And the power of the power supply is preferably 1.2 times of the total power. It is the rule 80%. It can improve the service life of the power supply and the LED strip light, and avoid burning to result in a short circuit.

*Calculating power for your LED strip lighting step by step: How to calculate power for led strip lights?